Keeping the Alaska Earthquake Center’s seismic network of more than 250 stations powered through all sorts of conditions is one of the field team’s crucial tasks year-round. Many of our stations are powered by batteries and solar panels as they are in remote places of the state. Battery swaps are a key part of our summer work (Figure 1) because the health of the network the rest of the year highly depends on the resilience of the power source through winter conditions.

Knowing Alaska’s challenging conditions—sub zero temperatures for 4-6 months, darkness, snow, wind—we check the health of our power system every winter to monitor if and when stations might become glitchy or go offline. Many northern stations are programmed to switch from transmitting data continuously to sending periodic data bursts in the winter, in order to save energy. Regular monitoring determines if expected power use is atypical and might indicate a problem. To check the power-system health, we observe the general trends of voltage at each station and look for gaps, length of charging time, no charging time, and how the voltage drops off from one year to the next.

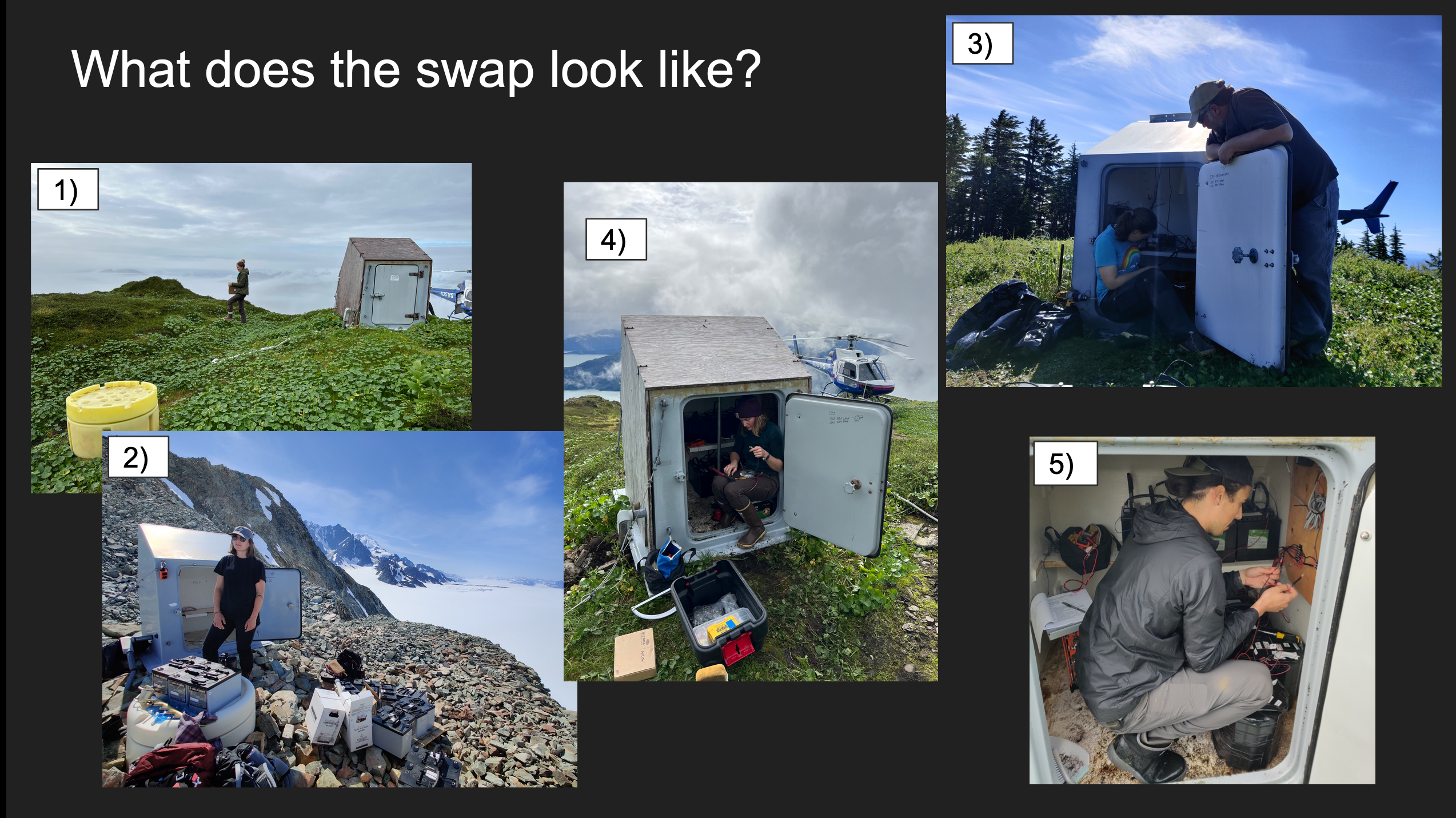

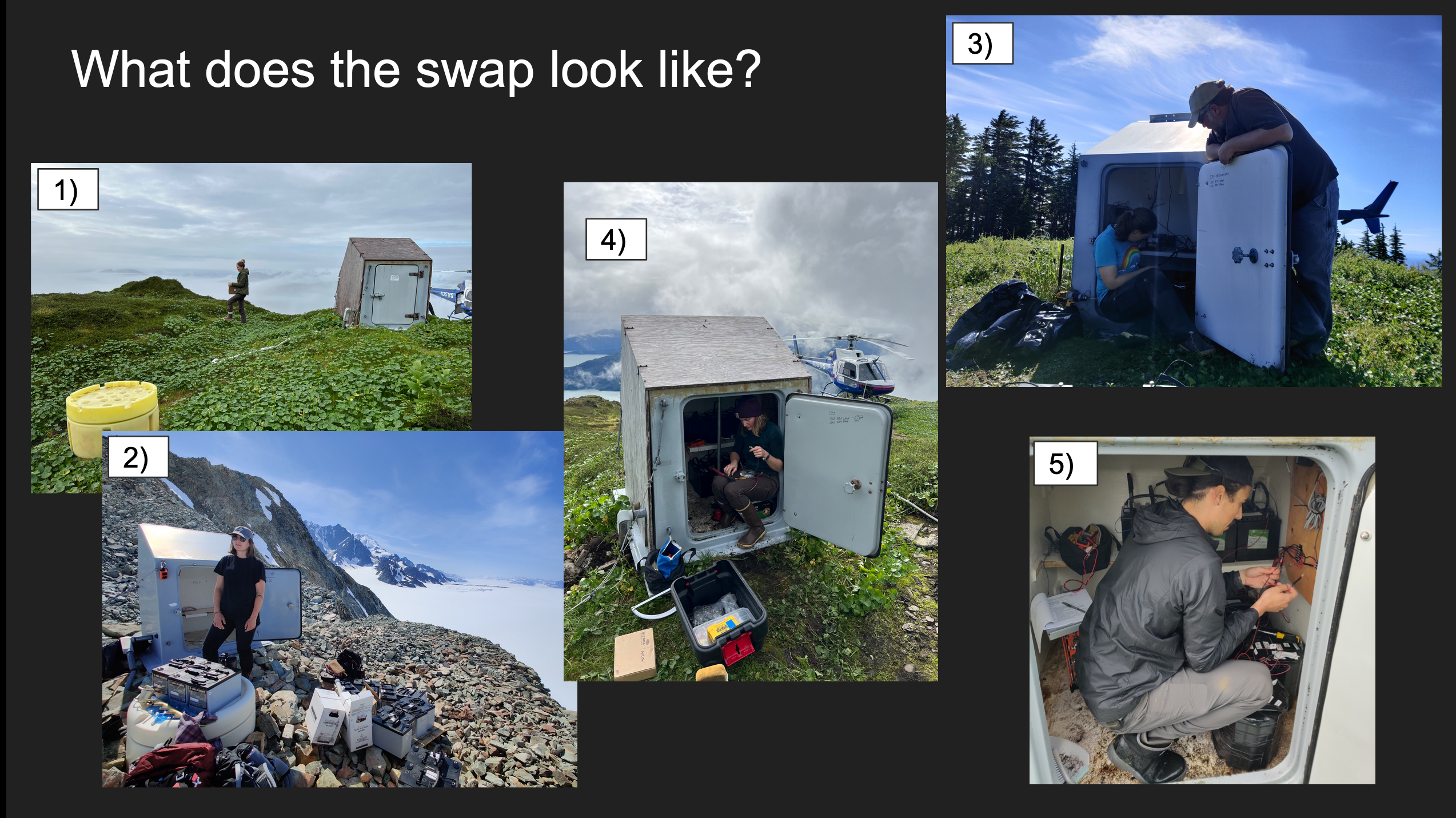

After deciding which stations need a battery swap, we start prepping the elements in the lab. We create or upgrade the electrical system that powers the seismometers and our communication systems. We pack the proper number of batteries and all the elements for a swap. We transport the batteries to the site, which could take multiple trips and involve driving them to a helicopter pickup location (mostly to reduce the flying time with heavy loads), then flying them by helicopter to our stations. Occasionally we use an external sling to drop them as close as possible to our station huts, depending on how many batteries need to be transported at the same time

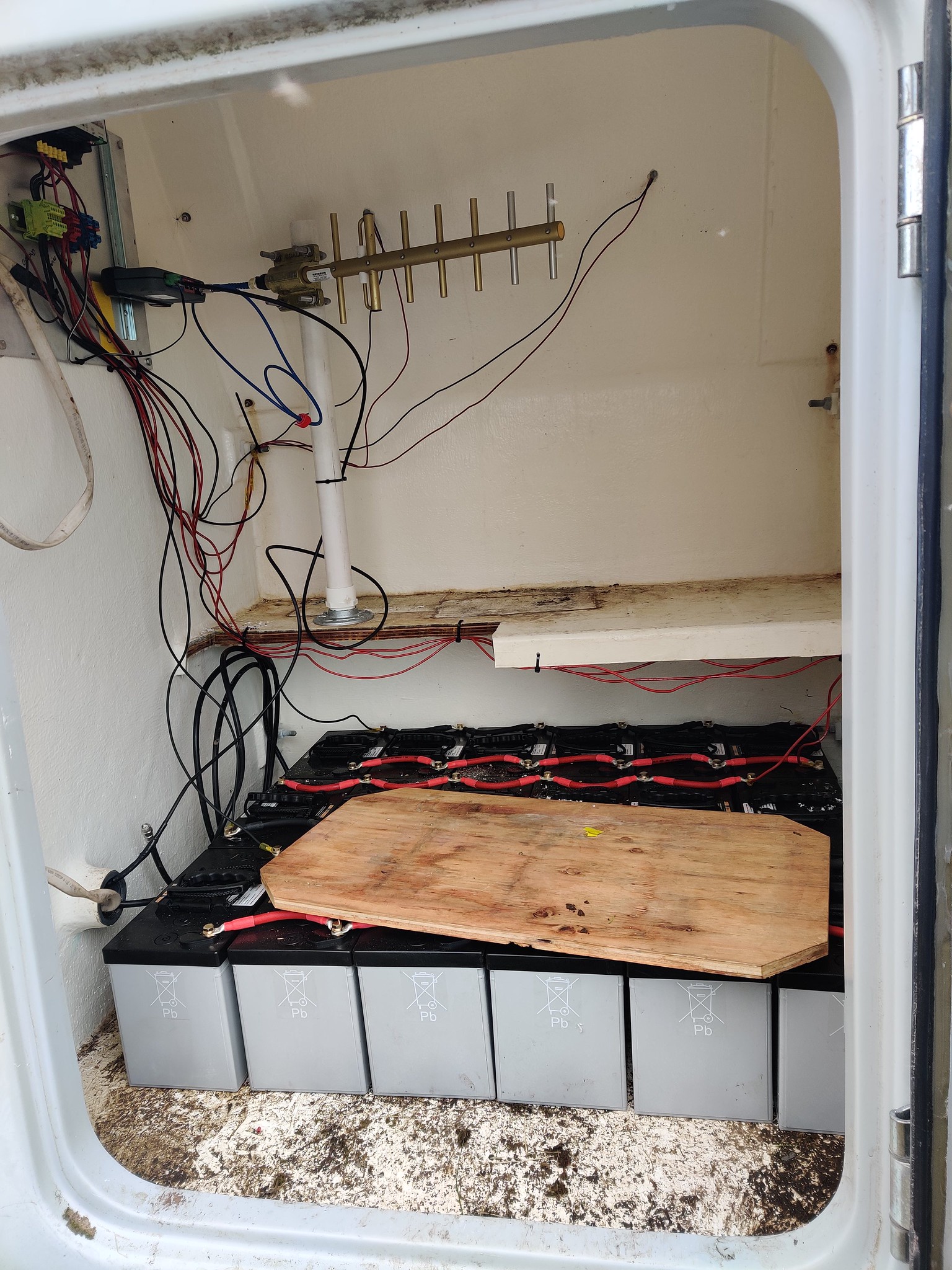

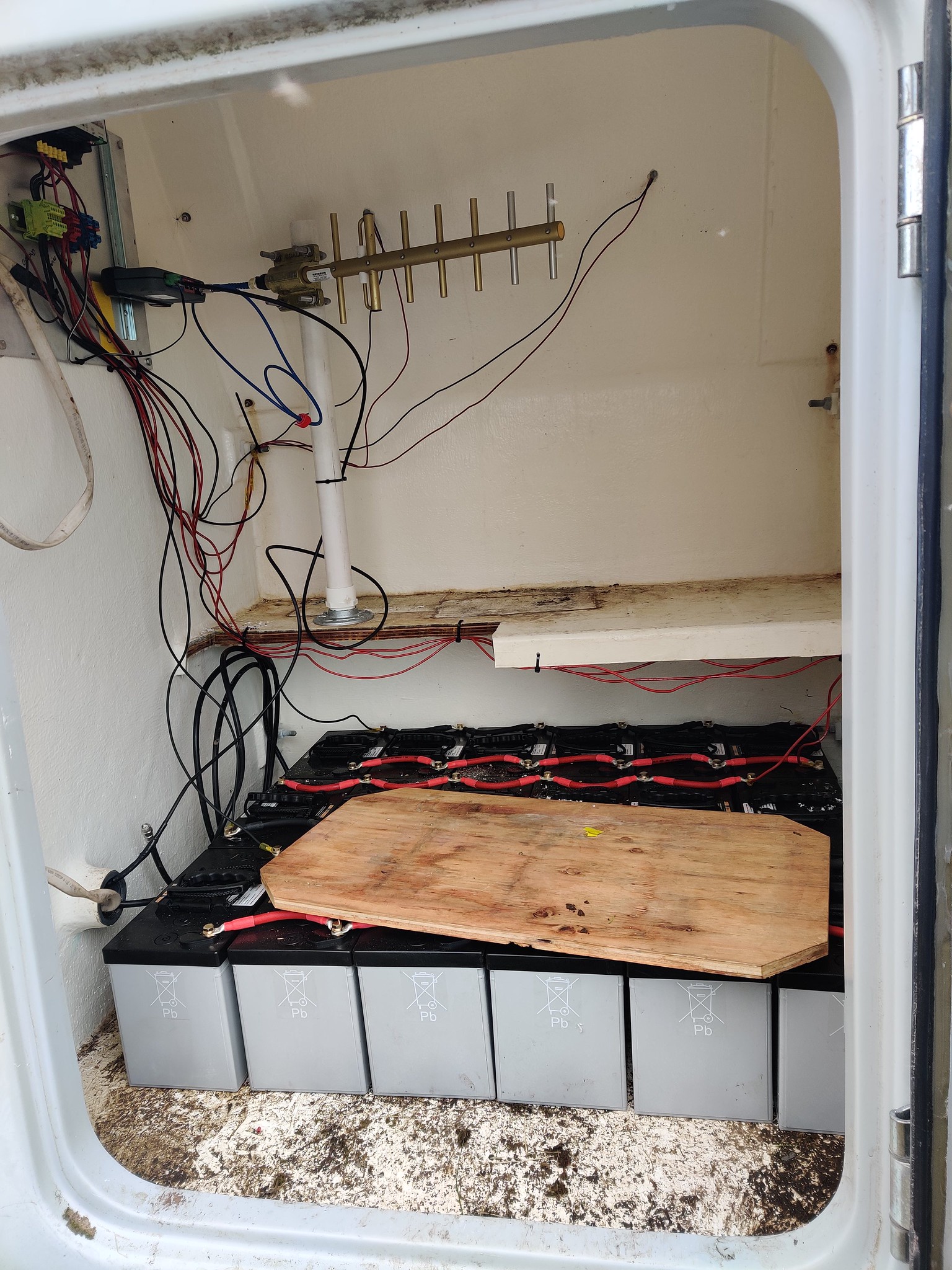

We use different setup methods for the different types of batteries in our network: lithium, AGM (Absorbent Glass Matt; an advanced type of lead-acid battery), and aircell batteries. Our standard operating procedure is to replace like with like. Each battery type requires different wiring, transporting, and handling. The lithium batteries are rechargeable 14V, are 55 pounds each, and we need 6-10 of them to power a station. We inherited these from the USArray Transportable Array deployment and they are supposed to last longer than other battery types. AGM batteries are also rechargeable, and give 12V-13V. They are the heaviest, at about 65 pounds each, and we need 18–24 of them to power all of a station’s elements (Figures 2 & 3). The aircells are 5V, non-rechargeable batteries that we use as additional support for the system in place. For example, we added aircells to Barry Arm station BAE to help power the video camera used for landslide observation.

Swapping batteries takes a lot of weight-lifting power! Say you are swapping AGM batteries. For example, swapping out 10 batteries means carrying 10 new ones in and 10 old ones out. At about 65 pounds (each!), that’s about 1,300 pounds carried for one swap!

My first summer out with the Earthquake Center, I became a pro at the battery swap. My first battery swap was one of the longest days in the field, as it takes a long time to get acquainted with the electrical system, and stay safe while learning. My last swap was one of the fastest days, as I knew the tricks (and it was raining).

Once the work starts on-site, we follow this five-step process (Figure 4):

This workflow is for the ideal world, but working in remote Alaska means that sometimes the unexpected is to be expected. Bears attack huts, and sometimes enter the station and chew on the cables—probably because they are tasty (to bears, anyway). The wind can destroy solar panels mounted on A-frames next to the huts. Snowfall in a particular place or year can be so high that it crushes the solar panels and the roof of the hut. Many different natural events can cause a power outage that was not predicted, but still needs to be resolved.

Being part of the field team means being adaptable and prepared for anything. Hopefully this short summary gives you an idea of just one part of what it takes to keep our stations running.